Photovoltaic Solar Energy

Workstations

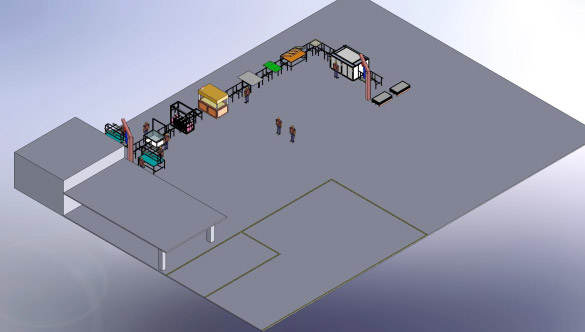

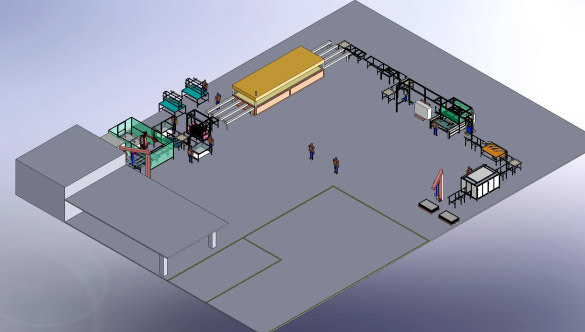

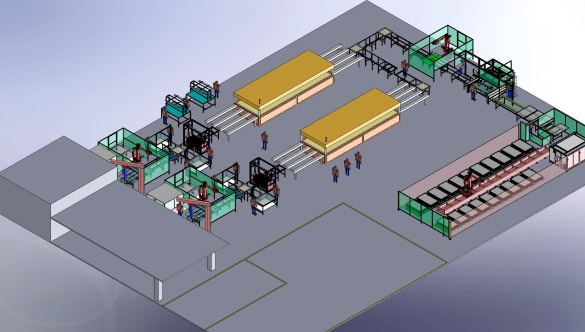

The workstations we offer in the manufacturing process of photovoltaic modules focus on providing solutions at the end of production of photovoltaic modules. Starting from laminated modules, we offer solutions for the different phases of production: Trimming the excess of EVA and backsheet, Framing Photovoltaic Module, Automatic placement of the junction box, Simulation, labeling and palletizing.

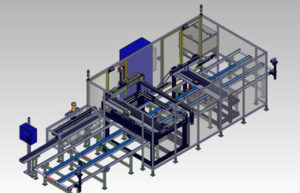

Our framing machine for modules with corner keys offers a compact and reliable solution using silicone to seal the module. The loading of aluminum and laminated module is manual with assistance to the operator and the process of silicone and framing is fully automatic.

Our framing machine for modules with corner keys offers a compact and reliable solution using silicone to seal the module. The loading of aluminum and laminated module is manual with assistance to the operator and the process of silicone and framing is fully automatic.

The most important technical features are:

- Different configurations of the cycle

- Silicone profile -> framing -> silicone glass -> silicone to the junction box. Cycle time: 110s.

- Silicone profile -> framing -> silicone to the junction box. Cycle time: 90s.

- Adaptable to any size of module.

- Adaptable to any form of junction box.

- You can use any silicone or sealant.

- Easily integrated into your existing production line.

High throughput machine for manufacturers who use screws in the profiles in their manufacturing process. Fully automatic machine in loading modules, silicone dosing and profiles screwing.

High throughput machine for manufacturers who use screws in the profiles in their manufacturing process. Fully automatic machine in loading modules, silicone dosing and profiles screwing.

The most important features are:

- Cycle time <50 seconds.

- Screwing of 4 sides of the module.

- Automatic screw feeding.

- Easy operation by SCADA on PC.

- A worker required to load the profiles (automatable on request).

- Easily integrated into your existing production line.

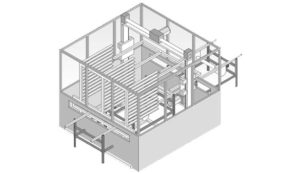

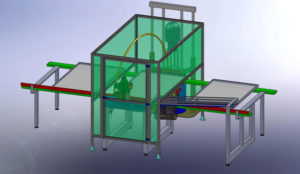

Automatic trimming workstation season using 6-axis industrial robot that provides total flexibility in trimming of PV modules.

Automatic trimming workstation season using 6-axis industrial robot that provides total flexibility in trimming of PV modules.

- Cutting with hot knife.

- Easily integrated into your existing production line.

- High productivity. Cycle time: 60 seconds.

- Automatic blade change that minimizes downtime (on request).

Market pioneer automatic junction box placement station.

Market pioneer automatic junction box placement station.

- Automatic Lifting of connections by artificial vision, special tool and robot.

- Dispensing of silicone (or other) by pump.

- Automatic feeding of junction boxes by linear vibrator.

- High productivity, less than 60 sec cycle.

- Easily integrated into your existing production line.

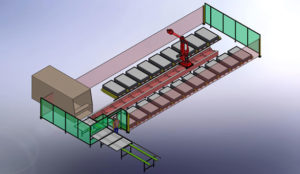

Automation of the simulation process, labeling and palletizing of modules. Based on your current configuration, we make the automation of the simulation, labeling and palletizing processes.

Automation of the simulation process, labeling and palletizing of modules. Based on your current configuration, we make the automation of the simulation, labeling and palletizing processes.

- We adapt your simulator to automate it.

- Automatic reading of the module bar code.

- Labelling machine with printer and applicator arm.

- Automatic Palletizing parameters according to your classification.

- Maximum flexibility in power, aesthetic…

- Up to 20 different palletizing positions.

- Easily integrated into your production line.

- Only one operator is required to connect the junction box to the robot.